Energy supply systems for the offshore, oil and gas industry

Conditions at sea, much like those on land, pose significant challenges for system components in the oil and gas industry. Cables, hoses, and energy supply systems must endure dirt, saltwater, vibration, extreme temperatures, high mechanical stress, and explosive environments during oil and gas extraction. Our products are designed to meet these demanding conditions. Whether on land or offshore drilling rigs, they ensure reliable energy supply for systems like the cantilever and highly dynamic pipe handling. They are lightweight and maintenance-free. With our engineering expertise and DNV- and NEK-certified chainflex cables, we provide ready-to-connect complete systems customized to your needs.

Energy supply systems for drilling equipment/top drives

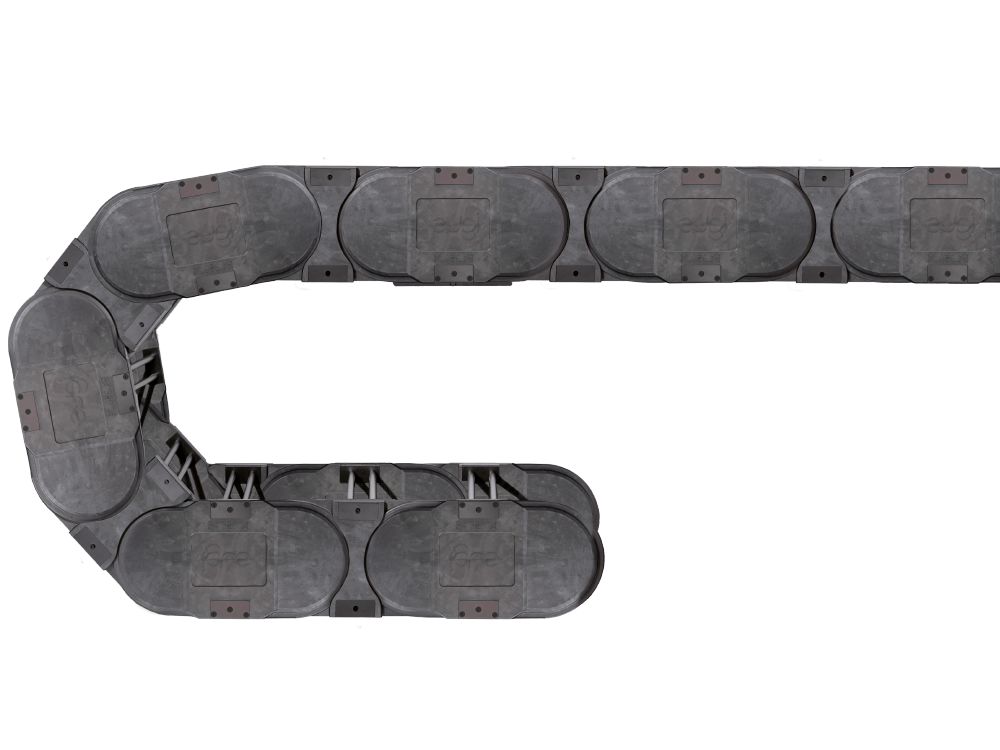

Heavy loads, high forces, and adverse environmental conditions are common challenges in the oil and gas industry. To address these, we offer robust and durable plastic energy chains and accessories designed to guide hydraulic lines, power cables, and signal cables on onshore and offshore drilling rigs, including drilling vessels and platforms.

Our products are suitable for a variety of applications, from guiding the top drive and cantilever to handling pipes. These tasks often involve long vertical travels on the drilling rig or supporting cable weights exceeding 200 kg/m on the drill skid. Installed in exposed areas, our energy chain solutions must withstand daily exposure to wind, weather, and corrosive environments.

We offer completely pre-assembled energy chains. This ensures fast installation and commissioning, providing a high level of planning reliability for the oil and gas industry.

Reliable cable guidance systems for top drives

Energy chains and service loops for top drive systems must withstand dynamic loads from vibrations and environmental influences. For both onshore and offshore drilling rigs, we provide heavy-duty energy chains and cables with accessories that ensure reliable cable guidance over long travels and under extreme conditions.

Our plastic energy chains offer superior corrosion resistance and low dead weight compared to steel energy chains. The structured interior separation enhances service life and maintenance-free operation, outperforming conventional service loop systems.

To ensure safe commissioning, we offer our cable guidance systems as complete solutions. We can help you with the entire design process, and deliver a ready-to-install solution.

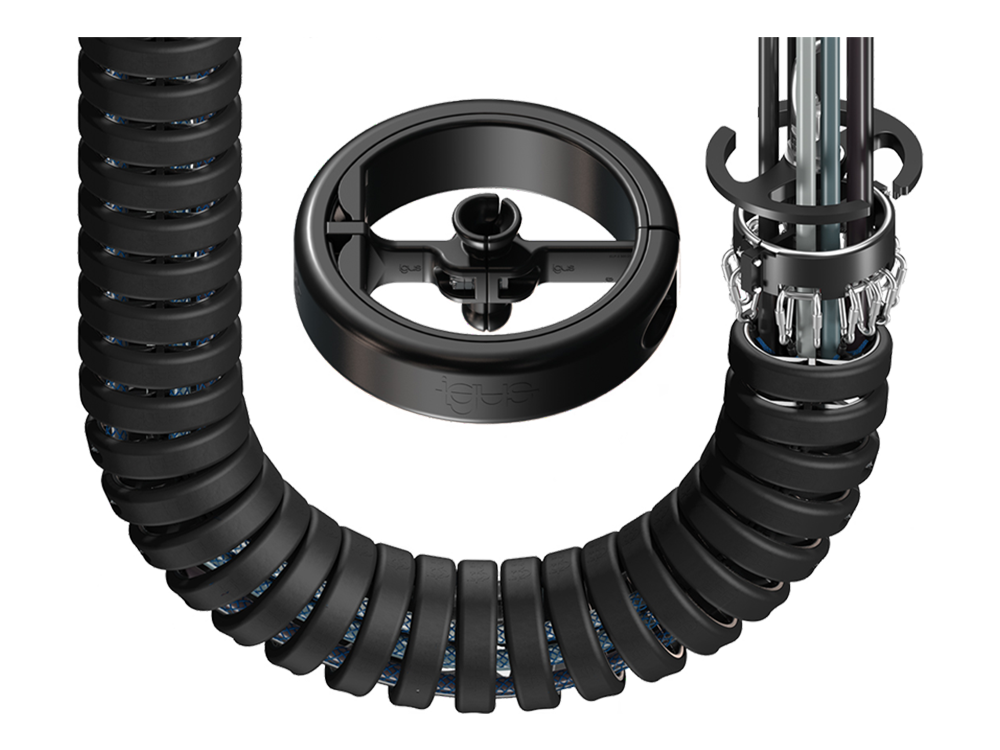

Modular e-loop energy chain system

- Combines the benefits of a plastic energy chain and a high-strength pull rope.

- Ensures complete strain relief: pull rope transfers tensile forces to mounting brackets and structure.

- Practical: allows individual cable replacement.

- Great chemical and UV resistance

chainflex special cables for the e-loop

Motor, data and hybrid cables for your top drive system

- Harmonizes with all top drive components for optimal fit in connector and chain

- Reduces costs by approximately 35% by eliminating the need for custom products

- Now DNV approved for the maritime sector

E4.1 series energy chain

- Robust and up to 70% lighter than steel

- Special interior separation prevents parts from falling out

- Modular design

Harnessed energy chain systems

- Harnessing time reduced by up to 95%

- Reduced assembly time – less machine downtime

- Manufacturing costs reduced

Energy supply systems for heavy-duty offshore cranes

For rotary and gantry cranes on ships and offshore installations, we offer comprehensive energy supply systems, including cables and trough systems, which can be provided as complete, ready-to-connect solutions. Our heavy-duty plastic energy chains are ideal for riser gantry cranes, surpassing festoon systems and steel energy chains with their corrosion-free operation and cable-friendly interior separation. The cable-friendly friction pair between the energy chain and cables significantly extends the service life of both the cables and the system.

For rotary cranes, we offer an RBR rotating energy supply as an alternative to traditional slip rings. This solution provides modularity and maintenance-free operation. The rotary module enhances system reliability, reducing downtimes and maintenance intervals by up to 90% compared to festooning systems and slip rings.

Top products for offshore cranes

Rotating energy supply

- Rotation systems with up to 900 degrees rotation

- Easy integration into your application’s structure

E4.1 series energy chain

- Robust and up to 70% lighter than steel

- Special interior separation prevents parts from falling out

- Modular design

Harnessed energy chain systems

- Harnessing time reduced by up to 95%

- Reduced assembly time – less machine downtime

- Manufacturing costs reduced

Energy supply systems for cable- and pipe-laying equipment

The equipment on pipe-layers must endure harsh sea weather and meet strict safety standards. Numerous heavy cables provide energy, data, and power to the tower, tensioner, welding systems, heavy-duty cranes, and retractable ship propulsion systems. For years, our energy supply systems have successfully protected and safely routed these cable packages. The E4.1 series e-chains are corrosion-free, vibration-resistant, and comparatively lightweight. They are designed to save space, which is a significant advantage on working ships where installation space is limited.

The same benefits apply to our rotation modules, which are used in rotary cranes as an alternative to slip rings. Using cable-friendly energy chains in the complete system can reduce maintenance costs by up to 90% compared to slip rings.

Top products for cable- and pipe-laying equipment

E4.350 e-chain system

- For large, heavy and stiff cables

- Tried and tested for heavy loads (up to 650kg/m)

- Resistant to wear, corrosion, oil, seawater

E4.1 e-chain series

- Robust and up to 70% lighter than steel

- No dropped objects thanks to special interior separation

- Modular design

RBR rotating energy supply

- Rotation systems with up to 900 degrees rotation

- Integrated strain relief and cable guidance directly in the guide trough

- Easy integration into the customer’s structure

Corrosion- and maintenance-free drytech® solutions for the offshore industry

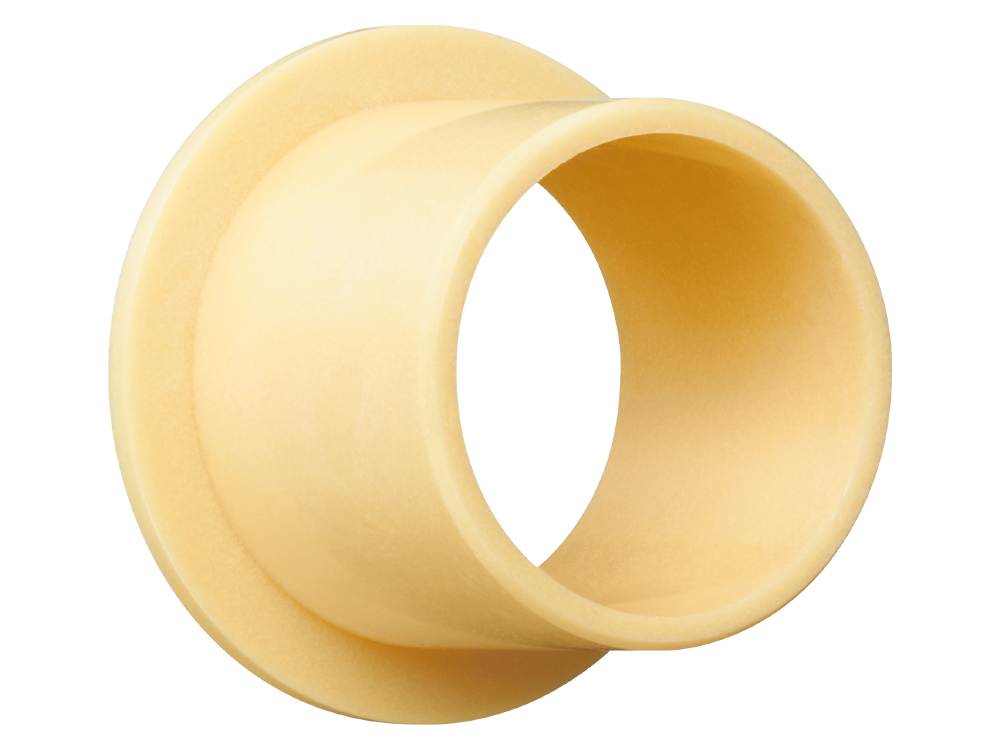

iglidur® bearings

Composite bearing solution from igus are completely maintenance-free bearings. They are suitable for extreme environmental conditions, and gives lowest possible friction and wear values in continuous and intermittent operation.

- iglidur® H370 – for underwater use

- iglidur® J – low wear

- iglidur® H – highly environmentally resistant

- iglidur® X – for high temperatures

- iglidur® TX1 – high loads, seawater resistant

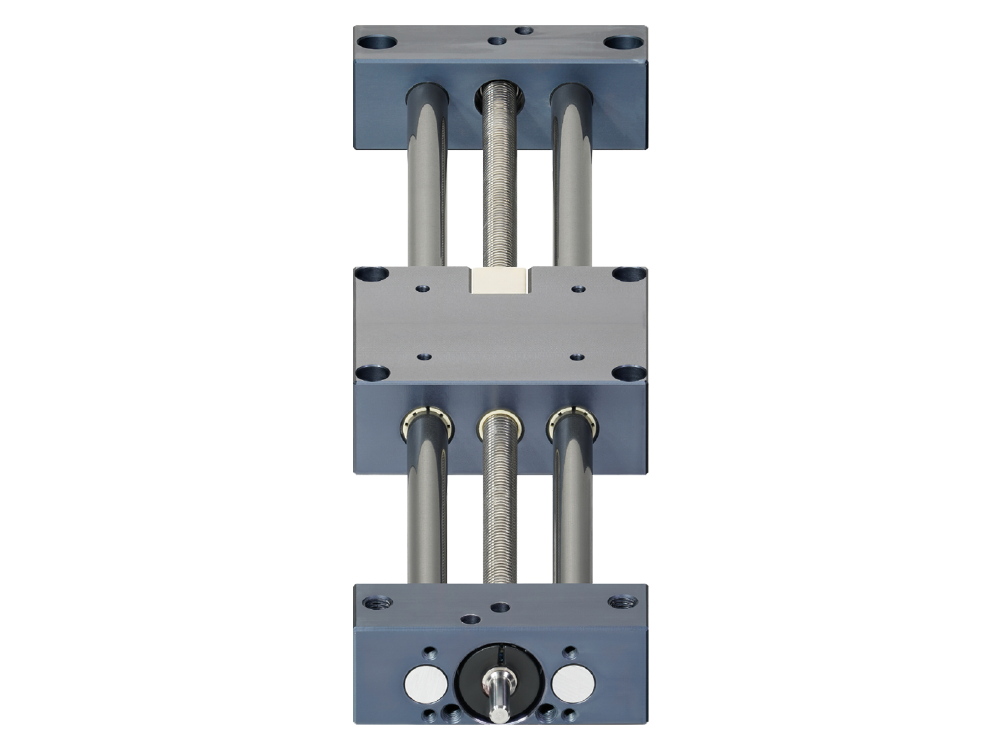

drylin® linear technology

igus has developed a combination of stainless steel and lubrication-free tribo-polymers espacially for the offshore industry:

- All steel components are entirely corrosion-free

- Use of 1.4571 and 1.4301 stainless steel

- Resistant to seawater and chemicals

- Ready-to-fit solutions from stock

- iglidur® J bearings for underwater use

Selected drytech solutions for the offshore industry

igutex – fibre composite plain bearings

Success stories with igus components in offshore industry.

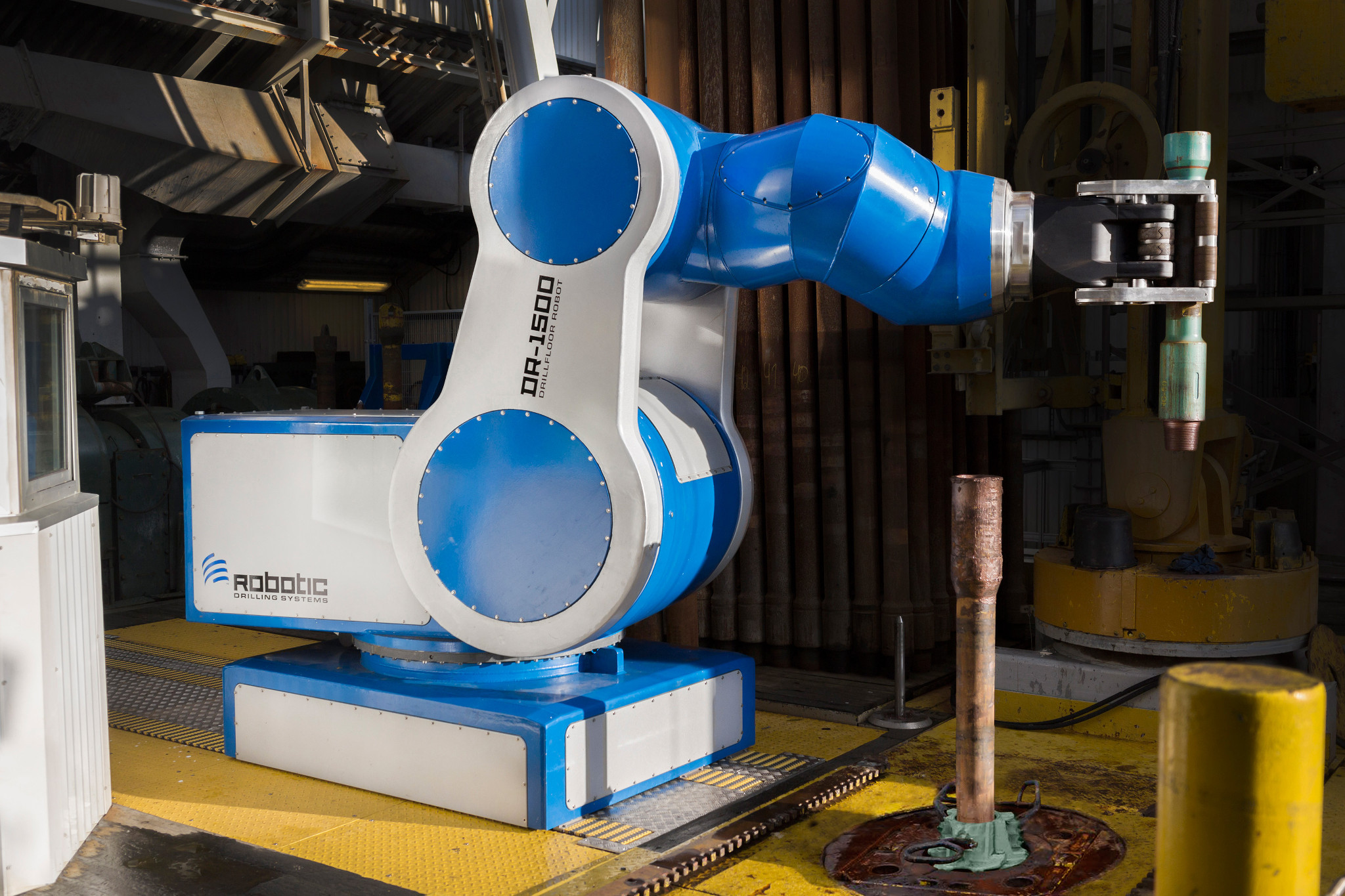

Revolutionary system for automating offshore oil exploration

Components used: Readychain systems: RBR, energy chains and chainflex cables

The Norwegian company Robotic Drilling Systems has developed a robotic system for automating the drilling processes on the platform after many years of research and development work. Energy chains from igus ensure reliable energy supply under extreme conditions.

Environmentally friendly vessel surface cleaning concept with lubrication-free igus plain bearing and linear technology

Components used: Plain bearings, linear guides and servo motor

Millions of tonnes of harmful substances from paints and varnishes end up in the oceans when operators maintain the surfaces of their vessels and offshore platforms with open-blasting methods. An environmentally friendly alternative: RoboCoat. With the help of the multi-functional robot from the Norwegian company Remotion, material residue is recycled. The lubrication-free linear guides and plain bearings from igus contribute to achieve this goal.